Wind

Empowering Wind Turbine Monitoring

7Countries powered

by WindMETER

Fiber Bragg Grating has become the natural choice for structural health monitoring in harsh environments and demanding applications such as in Wind Turbine Industry.

This passive technology is a powerful tool for wind turbines monitoring allowing the installation of simple sensing networks with drastic cable reduction and providing cost-effective, flexible solutions for multi-megawatt wind generators, hence optimizing the structure safety and boosting power yield.

Wind

METER

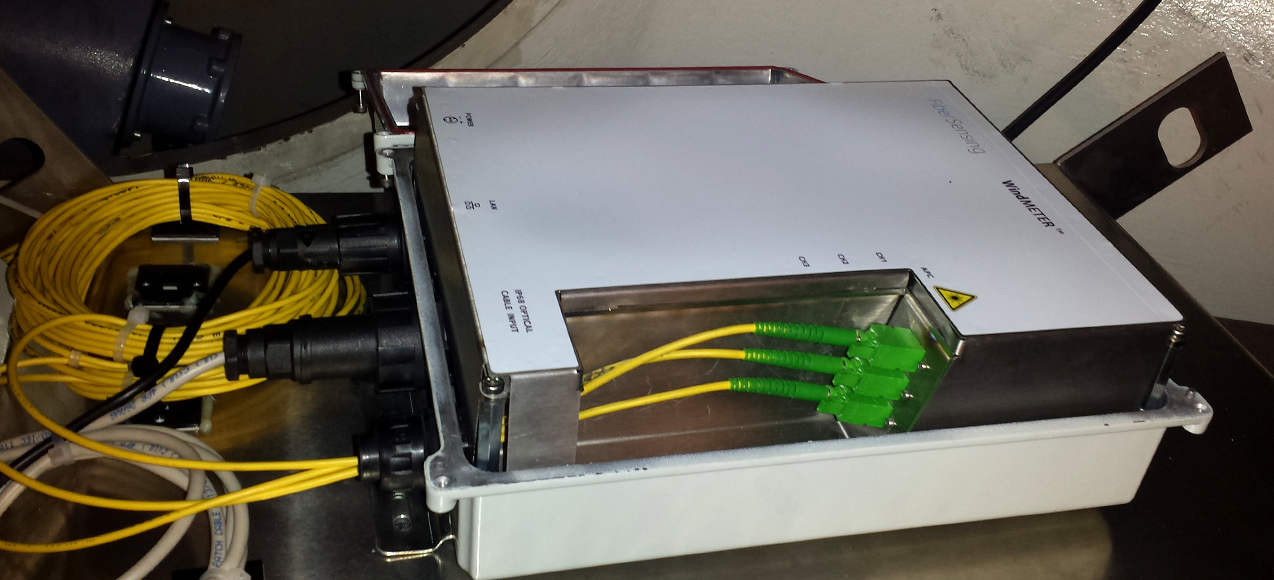

FiberSensing has envisioned and built an advanced blade monitoring system, WindMETER, which integrates both strain and temperature sensors in a single fiber cable and a high performance measurement unit.

This innovative system is characterized by its long lasting performance, attained by a built-in standard, which allows all measured data to be auto-calibrated in each 10 ms.

WindMETER can be integrated into a wide array of applications, leveraging solutions such as:

- Pitch

Control - Condition

Monitoring - Load

Assessment - Blade Design

Validation - Vibration

Monitoring - Ice

Detection

FBG sensor technology matches perfectly the requirements for blade monitoring due to its intrinsic characteristics

- Multiplexing of different parameters in a single chain

- Immunity to EMI/lightning and electrical isolation

- Embedding capability during blade manufacturing

- Signal Integrity

Specifications

| Temperature Range | -20ºC to 60ºC |

| Power | 24VDC |

| Consumption | 15W |

| Optical Communication Protocol | Profibus |

| Ethernet Interface | Yes |

| IP65 Enclosure | Yes |

| Up to 100 Samples/s | All Sensors |

| GFRP, PU | Encapsulated |

| Sensor Accuracy | ±5 με |

| Measurement Range | ±5000 με; -20ºC to 80ºC |

| Accelerometers | On Request |

WindMETER Includes: 1 measurement unit, 12 strain sensors, 12 temperature sensors & cabling. Optional: FGB Accelerometers.

Reference Customers

-

Offshore Wind Infrastructure Application Lab

Offshore Wind Infrastructure Application Lab -

Professionnels de l'Éolien

Professionnels de l'Éolien -

Aerospace Subsidiary of the European Aeronautic

Aerospace Subsidiary of the European Aeronautic

Defence and Space Company (EADS) -

National Renewable

National Renewable

Energy Center -

Energy Research Centre

Energy Research Centre

of the Netherlands -

Institute of Mechanical Engineering and Industrial Management

Institute of Mechanical Engineering and Industrial Management

Market

Growth

Two years after developing and testing WindMETER, FiberSensing boosts its sales and continues to thrive in the challenging wind business industry.

Reaching 264% of market growth was achieved by the close collaboration with strategic partners and technology integrators.

- 20101st Prototype

- 7 Major Exhibitions

- 8 h Installation Time

- 4 h Calibration Time

“WindMETER is a very reliable and robust system.” — INEGI, Portugal

“Compact, robust design, reliable operation.” — ECN, The Netherlands